After the failure of my $16 battery tab spot welder, I saw Kevin Dark’s DIY version.

After the failure of my $16 battery tab spot welder, I saw Kevin Dark’s DIY version.

But it wasn’t exactly what I needed, so I decided to build a modified version.

The Modified Dark Welder, or Dark Welder 2.0, has a foot switch that triggers a precise welding current pulse that is always the same length of time – no matter how long you hold down the button.

And in my new version, the button is now a foot pedal to keep your hands free.

The best part is: IT WORKS!

Off we go:

Stuff mentioned in the video:

- Check out Kevin Dark’s original welder

- Kevin Dark’s YT channel

- Capacitor Charge calculator

- Capacitor Discharge calculator

Also, don’t miss his nifty 18650-powered DIY electric skateboards!

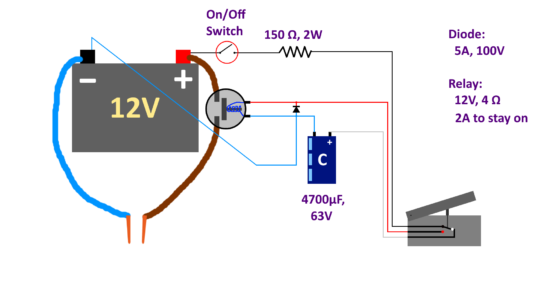

Schematic

Click to view larger version:

Parts List (some affiliate links):

Parts List (some affiliate links):

- Gebildet Pedal Switch

- 4700 uF 63V electrolytic capacitors

- Schottky 5A 100V diodes

- 150 ohm 2W resistors

- Copper nails

- Lighted pushbutton switch

- 12V, 10Ah, 150CCA lead acid battery

- 16mm^2 wire

- Large domino (screw terminals to hold welding cables + copper nails)

That’s all, folks!

Hi Scottie.

Although your design for the spot welder is a slight improvement on Kevins,it falls short in as much as you have not addressed that over time the contacts will get pitted and weld themselves together.the addition of a capacitor and a resistor across the contactor terminals will do much to aliviate the arcing much the same as a condenser was used in a car distributor to help protect the points back in the day.

also it would be very easy to add a visible or audible device to indicate the fact the contacts were welded

together.

Hope thats given you something to think about.

Have a nice day.

Hello,

Thank you to share the modification for the Kevin’s spot welder.

Is it mandatory to have a 4700uF 63v? I have one on 25v is it enough?

Thank you in advance for your answer.

Happy new year.

Maurice

That should be just fine. I just went a bit nuts with the 63V rating – I like to over-design things!

Thank you very much for your answer.

Best regards.

Maurice

Have you done any further improvements on this? I would add an led with resistor to indicate a good contact of welder probes. Like from batt positive to probe going across the relay etc. You could also automate the weld by using the same indicator to trigger the switch via a mosfet etc.